I. Overview

Ammonia decomposition of hydrogen furnace based industrial ammonia as raw materials, in the role of a catalyst, thermal decomposition of the hydrogen-nitrogen mixture containing 75% H2 and 25% N2 of. After purifier mixed gas, the residual ammonia content less than 2 ppm, dew point up to -70 ° C, the oxygen content is less than 3 ppm. Sent ammonia decomposition of hydrogen furnace gas production 5 to 500NM3 / h.

II Introduction

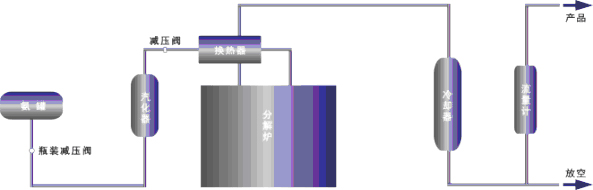

Available to the user of liquid ammonia cylinders or liquid ammonia tank to provide a source of ammonia. Liquid ammonia after ammonia vaporizer pressure stable gaseous ammonia, ammonia after pressure reducing valve can be directly into the ammonia decomposition furnace to decompose, decomposition of the mixture of hydrogen and nitrogen. A mixed atmosphere is cooled through a heat exchanger and water purification treatment was conducted after the flow control. Ammonia decomposition of hydrogen furnace by a heating element, temperature control and decomposition furnace; heating element consists of a low watt density of the nickel-chromium alloy as a heating element to ensure a long period of use, using a vacuum filter forming refractory fiber insulation, ensuring adiabatic quality, U-shaped decomposition furnace corrosion-resistant high-nickel alloys containing nickel catalyst. Purification devices the deaerator (on the atmosphere, the oxygen content of the special requirements of the customers to choose), composed of cooler, molecular sieve attached to the dryer and valves, electrical control. Purified by means of two molecular sieve adsorption dryers, two molecular sieve adsorption dryer cycle, one of them in the adsorption of impurities, other emissions in the desorption of impurities. Molecular sieve adsorption removal of water and residual ammonia gas, impurities in the gas content of less than 1 ppm. Evaporation of liquid ammonia storage system flow diagram

Decomposing furnace: the decomposing furnace decomposition furnace, furnace, chassis, heating elements, valves and meters, and so on.

Ammonia decomposition hydrogen plant flow diagram:

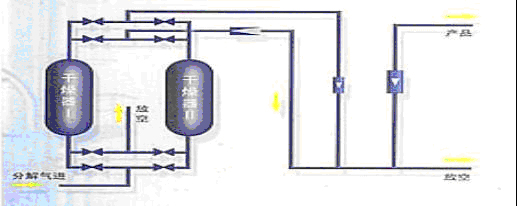

Purification: deaerator (on the atmosphere of the oxygen content of the special requirements of the customers to choose), cooler, molecular sieve adsorption dryer and valves group, electrical control.Ammonia decomposition purification device flow diagram

The AQ series ammonia decomposition gas generating apparatus advantages:

l low cost: This system is a simple mixture of hydrogen and nitrogen, with less investment than water electrolysis hydrogen, small size, low energy consumption and high efficiency.

l reliable: automatic temperature controller, valves regulate the flow, without the need for specially trained operator, you can get continuous, stable gas. High quality catalyst, heat-resistant stainless steel, nickel-chromium alloy heating element and stainless steel valves so that the entire system last longer.

l easy to use, the compact structure, small footprint, a skid-mounted as a whole; installation process is simple, no infrastructure, placed in place, connected to water, electricity, and out of the trachea can be put into normal production.

l high security, low decomposition pressure to 0.05 MPa; decomposition, random fluctuations in the nominal gas production within the gas tank, under normal circumstances without storing hydrogen; anaerobic hydrogen production, hydrogen whole process are oxygen-free environment.

4) Application:

Metal heat treatment: stainless steel, a variety of precision strip, wire and steel and alloys,

Brass, copper, copper annealing protective atmosphere

Metal reduction: reduction of tungsten and molybdenum, iron reduction in a reducing atmosphere

Powder metallurgy: iron, copper restore reducing protective atmosphere

Other: magnetic materials, special ceramics, diamond products, hard alloy shielding gas. 24-hour service: 13812758187